We can offer maintence contracts for larger commerecial customers and cleints with ongoing servicing testeting maintenace and review.

We can also offer the following maintence and testing through our team of engineers.

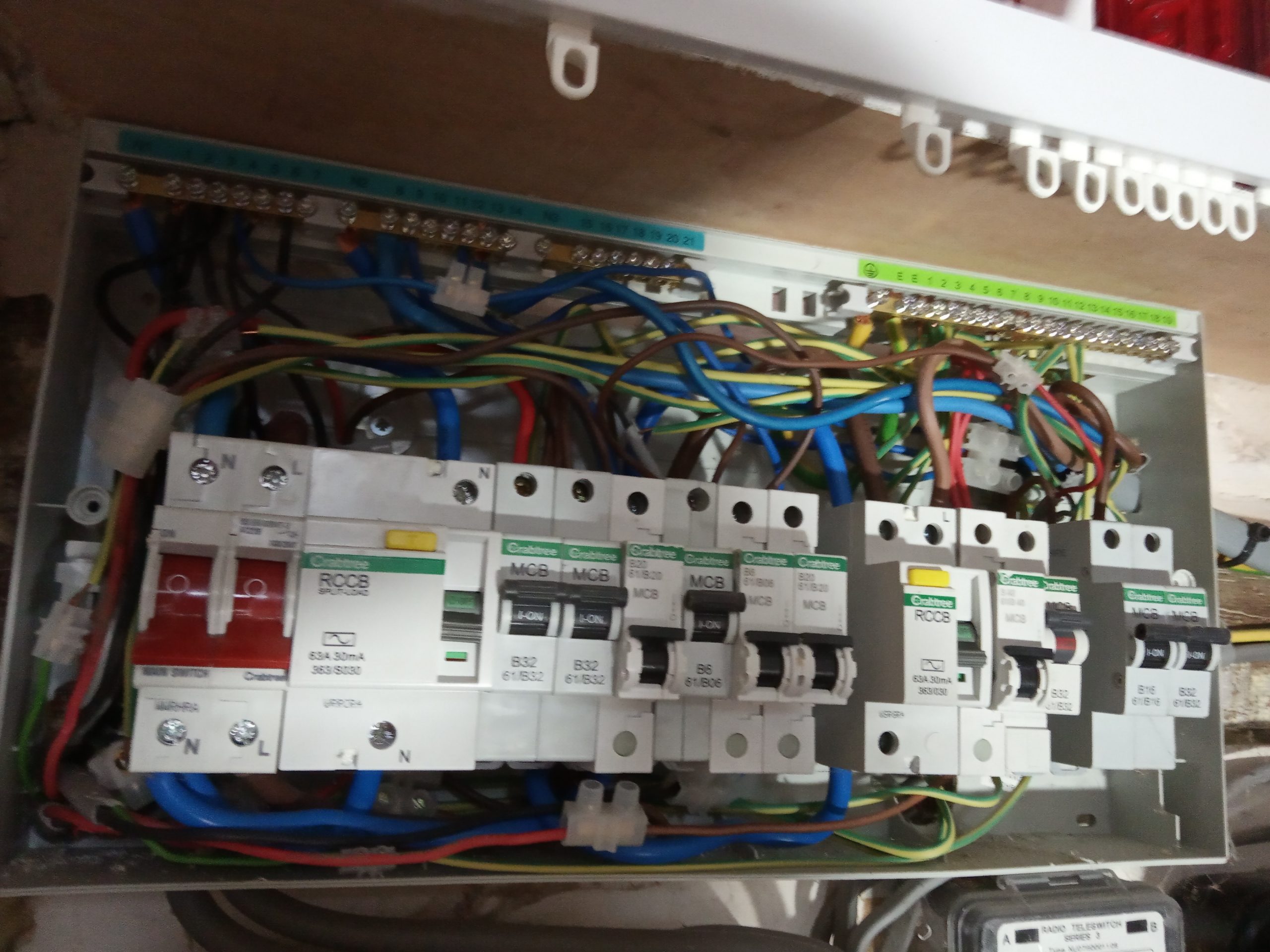

- Review of current electical installation

- Up to date survey and anylisis

- Overview and recomendation of system alteration

- Certification and summary of current system

- Out of hours call back as standard

Types of Preventive Maintenance

There are two main types of preventive maintenance: calendar-based maintenance, and usage-based maintenance.

Calendar-Based Maintenance

Calendar-based maintenance is the most common type of preventive maintenance. It uses software to set up a recurring, time-based maintenance schedule. Depending on the type of asset, intervals may be weekly, monthly, quarterly, or annually.

Usage-Based Maintenance

Usage-based maintenance relies on how much an asset has been used, rather than the amount of time that has passed, to determine PM checks. Meter readings are logged in a company’s preventive maintenance software, and when specified measurements are reached, a task will automatically be created for a routine check.

Benefits and Advantages of Preventive Maintenance

Ultimately, the primary benefits of preventive maintenance come down to reliability. As you keep each asset in good repair, it’s less likely to break down and cause downtime

Extension of Asset Lifetime

Equipment and machinery do not live forever. A planned maintenance approach maximizes the value of an asset by making sure it gets the proper care to meet (and possibly exceed) its projected life expectancy.

Increased Safety and Reduced Risk of Injury

The price of employee safety is never too high. Preventive maintenance keeps equipment in good order and running as expected, reducing accidents and malfunctions that could result in injury to employees.

Increased Savings

Preventive maintenance increases savings by allowing companies to anticipate repairs needed in the near future. This reduces unplanned downtime and corrective repairs, which can be more costly than planned maintenance.

Optimized Resource Allocation

With planned maintenance comes better control of your employees’ schedules. You can arrange for more efficient and effective procedures, keep scheduling expectations, and avoid paying overtime to operatives

Recent Comments